When it comes to medical imaging, X-ray technology is an invaluable tool that can provide important diagnostic information. X-ray machines consist of several components, and one crucial element is the X-ray grid. The X-ray grid is used to enhance image quality by reducing scatter radiation and improving image contrast. Choosing the right X-ray grid for your X-ray machine is essential for ensuring accurate and clear imaging results. In this article, we will discuss the factors to consider when selecting an X-ray grid for your X-ray machine.

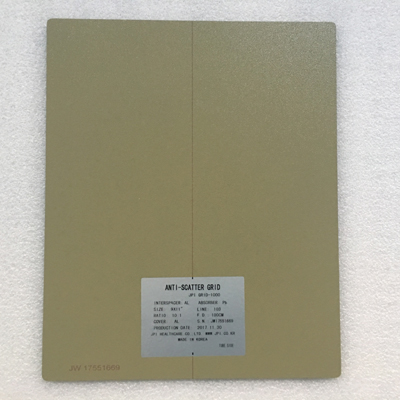

Before we delve into the selection process, let’s understand the basics of an X-ray grid. An X-ray grid is a device composed of thin lead strips alternating with radiolucent material. The primary function of the grid is to absorb scatter radiation that arises when X-ray photons interact with the patient’s body. Scatter radiation can significantly reduce image quality by producing a hazy background known as “grid lines.” By absorbing scatter radiation, X-ray grids help to enhance image contrast, resulting in sharper images.

The most important factor to consider when choosing an X-ray grid is its ratio. The grid ratio refers to the height of the lead strips compared to the distance between them. The most common grid ratios are 6:1, 8:1, 10:1, and 12:1. Higher grid ratios provide better scatter radiation absorption but require higher X-ray tube technique factors. Generally, a 10:1 or 12:1 grid ratio is ideal for general radiography, as it effectively removes scatter radiation without excessively increasing patient dose.

Another critical aspect is the grid frequency, which represents the number of lead strips per inch or centimeter. Higher grid frequencies result in smaller and thinner lead strips, enhancing image quality but increasing the cost of the X-ray grid. A grid frequency of 103 lines per inch or 40 lines per centimeter is commonly used for general radiography. However, higher grid frequencies, such as 178 lines per inch or 70 lines per centimeter, are recommended for specialized imaging applications that require superior image quality.

In addition to the grid ratio and frequency, the grid material is also crucial. Various materials, such as aluminum, carbon fiber, and hybrid grids, are used in manufacturing X-ray grids. Aluminum grids are the most commonly used due to their cost-effectiveness and good absorption capabilities. However, they tend to be heavier and can cause image degradation if not properly aligned with the X-ray beam. Carbon fiber grids are lightweight and offer excellent absorption properties, but they are more expensive. Hybrid grids combine the benefits of both aluminum and carbon fiber grids, providing a good balance between cost and performance.

It is also essential to consider the grid’s focal range, which refers to the range of X-ray tube-to-grid distances within which the grid performs optimally. Different X-ray machines have varying requirements for focal range, and selecting a grid that matches your machine’s specifications is crucial. Using a grid outside the recommended focal range can result in suboptimal image quality and increased patient dose.

Lastly, the size of the grid should correspond to the size of the X-ray machine’s imaging field. Using a grid that is too small can lead to grid cutoff, where the edges of the grid obstruct the X-ray beam, resulting in poor image quality. On the other hand, a grid that is too large may not fit properly or increase the patient dose unnecessarily.

In conclusion, choosing the right X-ray grid for your X-ray machine is vital for obtaining high-quality imaging results. Factors such as grid ratio, frequency, material, focal range, and size should be carefully considered to ensure optimal performance. Consultation with X-ray equipment manufacturers or radiology experts can provide valuable guidance in selecting the appropriate X-ray grid for your specific imaging needs.

Post time: Oct-17-2023